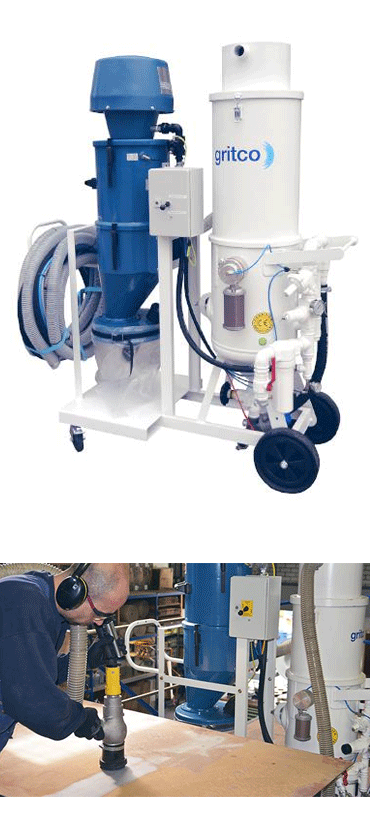

VACUUM BLASTING MACHINES

Vacuum, or dust free blasting is ideal for spot repairs, welding seams and/or in-situ blasting in working environments where dust- and abrasive pollution is to be avoided.

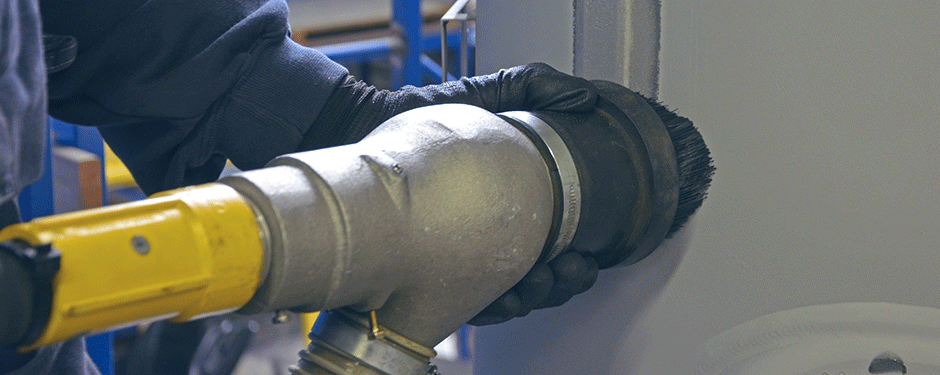

As the actual blasting is sealed off by a brush head, dust and abrasives are immediately vacuumed by a powerful suction unit. The separator and silo fully recycle the collected, used abrasives. The automatically contained dust can be simply discharged. Gritco’s vacuum blasting is a safe blasting solution for confined or critical areas (with a lower working speed compared to ‘open’ blasting).

- 100% dust free operation because of fully automated blasting & vacuum start/stop sequence

- Clean, abrasive free object surface after blasting

- No time-loss through automatic filter cleaning and dust discharge

- Easy disposal of collected dust in plastic bags

- Unit can be relocated and/or transported easily

- Wide range of brushes to fit all (flat, cornered, radiused) surfaces

Powerful benefits

Powerful benefits

- Long(er) uninterrupted blasting sessions because of 40, 60 or 100 liter blast pots

- Suited for all abrasives, also ‘heavy ones’ like steel shot or chilled iron grit

- Blasting patterns 50 or 75 millimeters

- (Spare) parts can be simply removed for quick maintenance

- Units are easily demounted in smaller parts for use in contained spaces (ships, tanks, etc.)

- Hose lengths up to 50 meters

Better blasting value

Better blasting value

- Renowned Nederman (Norclean) vacuum equipment for top results at low energy use

- Wear resistant metering valve handles all abrasives (also steel grits, fine aluminum oxide, etc.)

- Separate main air valve makes for almost wear- and maintenance free use

- Spray painted, galvanized and non-ferrous fittings

- Complete safety according to European Directive PED 2014/68/EU

Quality includes

Quality includes

- No dust and contamination which are collected in plastic bags for safe disposal

- Closed circuit blasting saves on abrasive costs