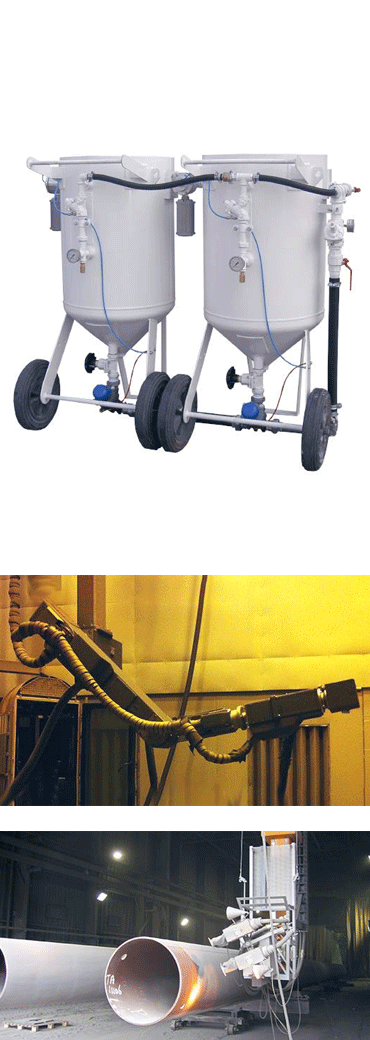

CONTINUOUS SERIES

Optimize robotized blasting with Gritco’s unique Continuous Series. Especially designed, horizontally placed blasting vessels with interconnected abrasive metering valves deliver an even, ongoing supply of abrasives.

One of the advantages of robotized blasting is an even, constant work flow. With common (double chamber) blast pots however the pressure instability – when refilling abrasives from the upper to the lower vessel takes place – is a well-known problem. Just as the construction’s height and poor accessibility of critical parts. Gritco’s Continuous Series tackles these problems with two horizontally placed Gritco blasting vessels with interconnected abrasive metering valves delivering a continuous flow of abrasives.

- Continuous blasting with optimal results, also during ‘vessel change-over’

- Meets with large air volume demands required for the large nozzles and high blasting pressure commonly used in robot blasting.

- (Spare) parts can be easily removed for quick maintenance

- Independently controlled, multiple abrasive outlet possibilities

Better blasting value

Better blasting value

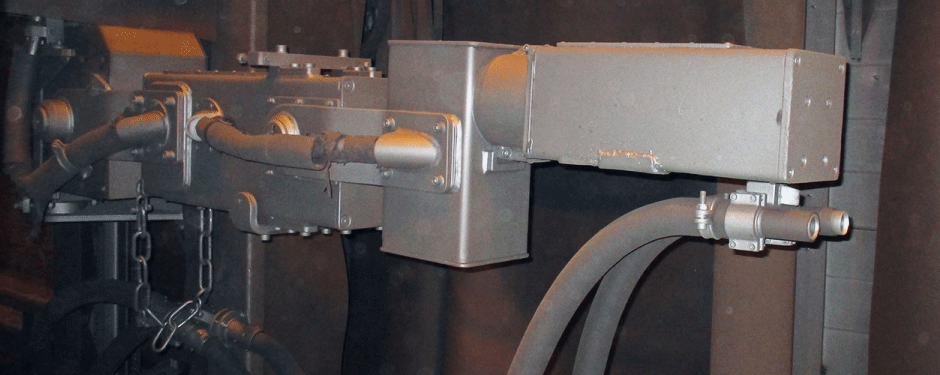

- Wear resistant metering valve handles all abrasives (also steel grits, fine aluminum oxide, etc.)

- Designed to endure extreme robotic blasting conditions such as long duration, compressed air pressure and volume, abrasive quantities, etc.

- Spray painted, galvanized and non-ferrous fittings

- Completely safe according to European Directive 2014/68/EU

Quality includes

Quality includes

- Easy integration in existing robot systems: low horizontal design fits under most abrasive silos